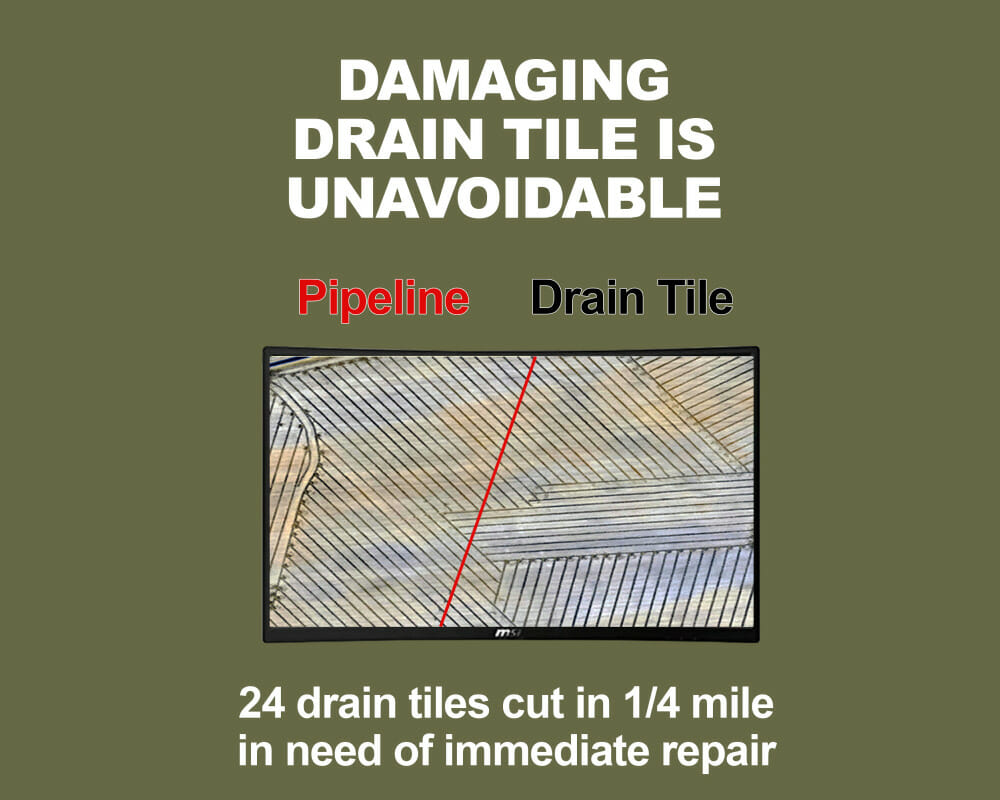

Mad Dog Materials has developed a product that provides reliable and low-cost repair of agricultural Drain tiles that have been severed by pipeline construction.

The benefits of Mad Dog Foam Bridges lie in their Material: a high-density Expanded Polypropylene foam, which makes them light enough for one worker to handle, yet strong enough to withstand the weight of the surrounding backfill upon completion of the repair. There has never been a safer, more reliable method for installing bridges and making drain tile repairs.

Learn More